Soil inspection is one of the most important yet often neglected steps in a construction process. Often, contractors will simply start working on a post or foundation and call it good. However, soils often have hidden characteristics that can lead to expensive problems down the road if you do not identify and deal with them properly. Different types of soil testing methods exist to help contractors and engineers assess soil properties.

In this blog, Graana.com, Pakistan’s smartest property portal, has discussed different types of soil testing done in construction.

What Is Soil Testing in Construction?

Soil testing is a process of determining the soil’s physical and chemical properties. Particularly, it is used in the construction industry to determine the type of foundation for a structure.

Types of soil testing in construction

Discussed below are the most common types of soil tests in construction.

Moisture Content Test

A moisture content test is a way to measure the amount of water in a substance. There are many different ways to do this, but all of them rely on the principle that water has a higher boiling point than most other substances.

By measuring the temperature at which a substance boils, it is possible to calculate the percentage of water in that substance.

The oven-drying method, calcium carbide method, torsion balance method, pycnometer method, sand bath method, radiation method, and alcohol method are all used to determine the moisture content of the soil.

Amongst all, the oven-drying method is the most popular approach; it involves weighing the sample soil, drying it in an oven at 110 degrees Celsius (+/- 5 degrees), and then weighing it again.

The water weight in the soil is represented by the difference between the before and after weights.

Atterberg Limit Test

This is another type of soil testing in construction. The Atterberg Limits are a series of moisture content tests on cohesive soils that can indicate soil plasticity.

The test helps classify soil and its plasticity characteristics, as well as evaluate near-surface soil shrink/swell potential. You can use it to identify different types of silt and clay, as well as assess the soil sample’s shrinkage limit (SL), plastic limit (PL), and liquid limit (LL).

Moreover, you must perform this test on a soil sample that has been dried in an oven at 105 °C for 24 hours. Following, crush the soil to a fine powder and pass it through a 2 mm sieve.

Place a small quantity (about 1 g) of the soil in a container, and add the water.

Furthermore, The moisture content of clay soil affects its firmness and behaviour. The behaviour of the soil sample determines the limit at which the change occurs.

The soil can be in one of four states, depending on the moisture content:

- Semi-solid

- Solid

- Liquid

- Plastic

Specific Gravity Test

The specific gravity test is a common procedure that you can use for soil testing in construction to determine the moisture content of the soil. It is based on the principle that the weight of a volume of material is directly proportional to the weight of an equal volume of water.

This property is known as density, and you can use it to measure the moisture content of soil by comparing its densities to that of pure water. By definition, the specific gravity of a substance is the ratio of its density to the density of pure water at 4 degrees Celsius.

The density bottle method, Pycnometer method, gas jar method, shrinkage limit method, and measurement flask method are some of the methods that you can use to determine it. Amongst these, the pycnometer methods and density bottle are used most often for soil analysis.

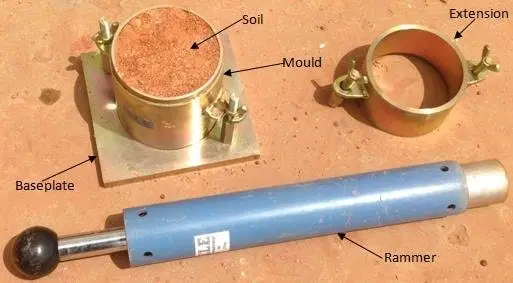

Proctor’s Compaction Test

Proctor’s compaction test is a basic soil testing procedure used to determine a soil specimen’s compressive strength. The test results can indicate the type of foundation on which a structure should be built, as well as predict the maximum load that it can support.

The Proctor’s compression test is widely accepted and easy to perform, making it an ideal option for field testing.

You can carry out the test procedure by compacting dry soil specimens in a metal container using a compaction hammer. You can use it to determine the soil’s compaction properties. After air-drying, you will have to separate the soil sample into four to six smaller samples.

Afterward, add water to alter their water content, ranging from 3% to 5%. Finally, they arrange samples in three layers in the Proctor compaction mold. You can then use a normal 5.5-pound hammer to strike each layer 25 times. Get to know how to improve bearing capacity of soil?

Dry Density Test

The dry density test is one of the most popular and commonly used tests for determining the unit weight or density of soils. It is also called the nuclear gauge method.

In this test, a nuclear gauge is calibrated with reference to water and then used to measure the dry density of soil.

A dry density test in the soil is carried out at 2 levels:

Core Cutter Method

The soil is extracted from the ground using a typical cylindrical core cutter, and the sample is weighed for testing. The sample’s water content is determined, and the dry density is calculated.

Sand Replacement Method

This level involves excavating a hole and measuring the soil’s dry density with it. Firstly, fill the hole with dry sand that is homogeneous in density.

Afterward, calculate the volume of the hole by dividing the mass of sand poured into the hole by the dry density of sand.

Importance of Soil Testing in Construction

Certainly, soil testing is an important part of any construction project as you can determine its composition and characteristics. This information is essential for designing a safe and stable foundation.

There are many other factors that signify the importance of soil testing in construction:

- Used in civil engineering and construction to determine soil suitability for a particular purpose

- Used to assess the impact of construction on the soil

- Helps to determine the type and quantity of soil required for a project

- Helps assess construction’s impact on soil and identify any potential problems

- Aid to determine soil suitability for specific applications, such as pavements or foundations

So, these are some of the major types of soil testing in construction that you need to know about. To read more about the construction sector of Pakistan, visit our blog.

FAQs

Here are some FAQs related to the soil testing for construction

Why is soil testing necessary for construction projects?

Soil testing is necessary for construction projects to assess the soil’s properties, including its strength, composition, and stability. This information helps engineers and architects determine the appropriate foundation design and construction methods.

How is soil testing conducted?

Soil testing is conducted by collecting soil samples from the construction site and analyzing them in a laboratory. The samples are tested for various parameters, such as moisture content, compaction, permeability, bearing capacity, and soil classification.

What are the benefits of soil testing in construction?

Soil testing provides crucial information about the soil’s suitability for construction, helping to identify potential issues such as soil settlement, instability, or poor load-bearing capacity. This information allows engineers to make informed decisions and design appropriate foundations.

Who performs soil testing for construction projects?

Soil testing is typically performed by geotechnical engineers or specialized soil testing laboratories. These professionals have the expertise and equipment required to conduct accurate soil tests and provide reliable analysis.

When should soil testing be conducted during a construction project?

Soil testing should be conducted during the initial stages of a construction project, preferably before the design phase. This allows engineers to incorporate the soil properties into the design and determine the appropriate foundation system.

What are the common tests conducted during soil testing for construction?

Common tests conducted during soil testing include moisture content test, compaction test, sieve analysis, proctor test, shear strength test, and consolidation test. The specific tests performed depend on the project requirements and soil conditions.

Can soil testing prevent construction failures or issues?

Soil testing plays a vital role in identifying potential construction issues and mitigating the risk of failures. By understanding the soil’s characteristics, engineers can design foundations and structures that are compatible with the site conditions, reducing the likelihood of problems during and after construction.

How long does soil testing for construction take?

The duration of soil testing for construction varies depending on the project size, site conditions, and the number of tests required. Typically, it can take a few days to weeks to complete the soil testing process, including sample collection, laboratory testing, and analysis.

Who interprets the results of soil testing?

The results of soil testing are typically interpreted by geotechnical engineers or professionals experienced in soil mechanics. They analyze the data and provide recommendations based on the specific project requirements and soil characteristics.