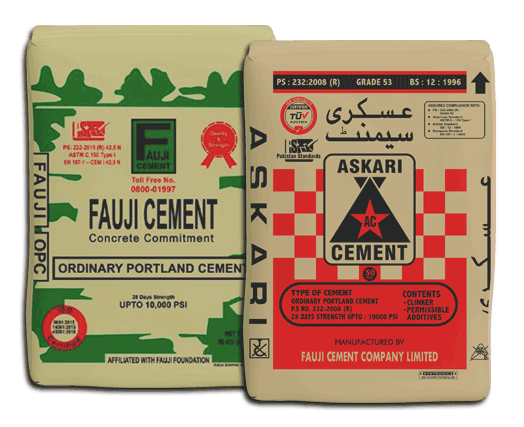

Askari Cement, Pakistan is a leading manufacturer and supplier of quality cement. The company has a strong reputation for producing high-quality products that meet the needs of a wide range of customers, including builders, contractors, and large corporations.

Graana.com gives an overview of Askari Cement below, including its history, products, and operations.

A Brief History of Askari Cement, Pakistan

Askari Cement is a subsidiary of Fauji Cement Company Limited (FCCL), which is a public limited company incorporated in Pakistan under the Companies Act, of 1913. FCCL is listed on the Pakistan Stock Exchange and is one of the leading cement manufacturers in the country.

It was established in 1997 and started operations in 1999. The company operates two cement plants in Wah and Nizampur, with a total production capacity of 8,885 tons per day. Askari Cement, Pakistan is known for its high-quality cement, which is manufactured using state-of-the-art technology and the latest equipment.

Products Offered by Askari Cement, Pakistan

Cement is one of the most essential building materials used in construction. It is a binder that holds together different building components like bricks, stones, and concrete blocks. It is produced by heating a mixture of raw materials like limestone, clay, and sand in a rotary kiln at high temperatures.

During this process, the raw materials undergo a chemical reaction that results in the formation of a clinker. The clinker is then ground into fine powder, which is known as cement.

There are different types of cement available in the market that are specifically designed to meet different construction needs. Discussed below are some of the most commonly used types of cement.

Ordinary Portland Cement (OPC)

OPC is the most widely used cement in the world. It is a general-purpose cement that is suitable for all types of construction work. OPC is made by grinding clinker, gypsum, and small amounts of other materials.

It has high strength, and durability, and is ideal for making concrete for foundations, walls, and roofs. OPC comes in different grades such as OPC 33, OPC 43, OPC 53, and OPC 63. The higher the grade, the higher the compressive strength of the cement.

Sulphate Resistant Cement (SRC)

As the name suggests, SRC is resistant to sulphate attacks that occur due to exposure to sulphates present in soil and water. Sulphates can react with the cement and cause it to disintegrate over time. SRC is made by reducing the amount of tricalcium aluminate (C3A) in the cement.

C3A is responsible for the early strength gain of cement, but it is also highly reactive to sulphates. SRC is ideal for construction in areas with high sulphate content in soil and water, such as coastal regions.

Low Alkali Cement (LAC)

High amounts of alkalis can cause the concrete to crack and weaken over time. LAC is made by using raw materials that have low alkali content. It is ideal for construction in areas where the quality of aggregates is not known, or in cases where alkali-reactive aggregates are used.

Pozzolanic Portland Cement (PPC)

PPC is made by blending OPC with pozzolanic materials like fly ash, volcanic ash, and silica fume. Pozzolanic materials are known to enhance the durability and workability of cement. PPC has a lower heat of hydration and is ideal for construction in hot weather conditions. It is also suitable for making concrete for mass concrete structures like dams and retaining walls.

Blast Furnace Slag Cement (BFSC)

BFSC is made by blending OPC with blast furnace slag, which is a byproduct of iron production. It has excellent strength, durability, and resistance to chemicals and harsh weather conditions. It is ideal for construction in areas with high sulphate content in soil and water, as it is highly resistant to sulphate attacks.

Operations of Askari Cement, Pakistan

Askari Cement, Pakistan operates two cement plants in the nation: the Wah plant has a production capacity of 4,000 tons per day, while the Nizampur plant has a production capacity of 4,885 tons per day.

Both plants are equipped with the latest technology and equipment to ensure that the cement produced meets the highest quality standards. The plants use advanced quality control systems to monitor the production process and ensure that the cement meets the specifications of customers.

Askari Cement also has its own fleet of trucks to transport cement from the plants to customers across Pakistan. This ensures that the cement is delivered in a timely and efficient manner.

Corporate Social Responsibility

Askari Cement, Pakistan is committed to being a responsible corporate citizen and is actively involved in various initiatives that support the development of communities in the country. The company supports education, healthcare, and other social welfare projects in the areas where it operates.

It has also taken steps to reduce its environmental impact. The company has implemented various measures to reduce its energy consumption and minimise the amount of waste generated by reusing waste material in the production process.

Askari Cement Price

As of October 2023 cement price, the price of a 50 kg Askari Cement bag is Rs. 1195-1200. The price may vary with time, depending on different factors.

Conclusion

The company’s commitment to quality of cement, innovation, and customer satisfaction has helped it to build a strong reputation in the market. With its state-of-the-art plants, wide range of products, and commitment to corporate social responsibility, Askari Cement, Pakistan is well-positioned to meet the evolving needs of its customers and contribute to the growth and development of the country.

Frequently Asked Questions (FAQs)

Here are some frequently asked questions about Askari Cement.

What is the production capacity of Askari Cement?

The production capacity of Askari Cement is 9,000 tons per day.

What types of cement does Askari Cement produce?

Askari Cement produces Ordinary Portland Cement (OPC), Sulphate Resistant Cement (SRC), and Low Alkali Cement (LAC).

Is Askari Cement ISO certified?

Yes, Askari Cement is ISO 9001:2015, ISO 14001:2015, and OHSAS 18001:2007 certified.

Does Askari Cement export its cement?

Yes, Askari Cement exports its products to several countries, including Afghanistan, India, South Africa, Sri Lanka, and Tanzania.

What is the customer support contact information?

The details for customer service can be found on its official website, which includes phone numbers and email addresses.

Who owns Askari Cement?

Haris Manzoor is the MD & CEO of Fauji and Askari Cement Limited.

To read about Power Cement, visit the Graana Blog.