Fauji Cement Company Limited (FCCL) is a renowned cement manufacturer based in Pakistan, known for producing high-quality cement products. Established in 1992, FCCL has been a major contributor to the local cement industry, providing employment opportunities and boosting the country’s economic growth.

Graana.com provides a comprehensive overview of FCCL, including its history, operations, and commitment to sustainability as well as health and safety.

About Fauji Cement Company Limited (FCCL)

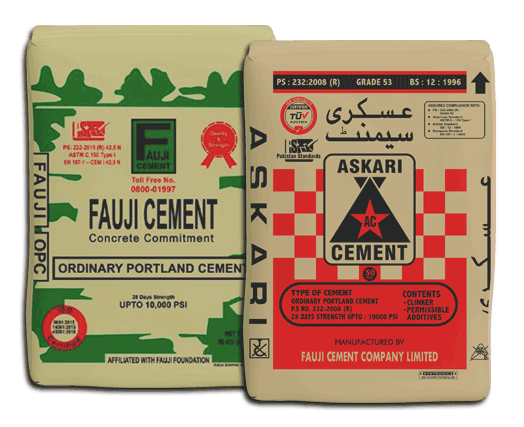

Fauji Cement Company Limited has been setting the benchmark for the cement industry in Pakistan for the past 31 years. In 2021, it successfully acquired Askari Cement Company Limited (ACL) and is now strategically located near hydroelectric power projects. It is also qualified for major construction projects in Pakistan.

FCCL operates three manufacturing sites in Jhang Bahtar, Nizampur, and Wah. The company has achieved significant progress, including the commissioning of Line 3 in Nizampur, which demonstrates its ability to consistently deliver high-quality projects.

The company employs state-of-the-art dust sequestration technologies, such as bag house filters, electrostatic precipitators, bag filters, and Critical Environment Monitoring Systems (CEMS), at all of its manufacturing plants to enhance its efforts to reduce suspended dust around the production areas.

Fauji Cement Company Limited – FCCL is currently undertaking a Greenfield project in D.G Khan, which it expects to complete by the second quarter of 2024. The construction of this facility will pave the way for eco-friendly industrial production on a larger scale.

After commissioning the D.G Khan manufacturing plant, FCCL will reinforce its position as the second-largest cement manufacturer in the northern region and the third-largest cement producer nationwide.

FCCL places great importance on sustainable development and reducing carbon emissions. In addition, the company has an extensive corporate social responsibility (CSR) footprint in the communities where it operates, which sets it apart from other companies.

Moreover, it is committed to producing high-quality cement in Pakistan and contributing to national growth. To maintain an eco-friendly manufacturing process and reduce carbon emissions, FCCL utilises a combination of solar power, waste heat recovery, and alternative fuels to fulfil over 40% of its energy requirements, resulting in a reduction of over 140,680 tons of carbon emissions in its operations.

Products

Fauji Cement Company Limited deals in the following products:

- Ordinary portland cement

- Sulphate resistant cement

- Low alkali cement

- Low heat of hydration cement

- Pamir cement (green cement)

Ordinary Portland Cement

Ordinary Portland Cement (OPC) is a type of cement that has common use in general construction projects. It is best suited for plain and reinforced cement concrete, brick and block masonry, pavements, and precast structures.

OPC is widely utilised in heavy infrastructure projects, such as bridges, flyovers, high-rise buildings, and industrial structures, due to its exceptional durability and strength. It is available in high-strength variations that are specifically designed for use in special structures that require additional strength, such as high-rise buildings and industrial structures.

These are manufactured by adjusting the ratios of key ingredients, such as silica, alumina, and iron oxide, to achieve the desired strength and durability. The use of OPC in construction projects not only ensures the longevity of the structure but also contributes to the overall strength and stability of the building.

Sulphate Resistant Cement

Sulphate-resistant cement (SRC) is a type of cement that is highly effective against all forms of sulphate attacks. It is particularly well-suited for use in underground construction, sewerage works, basements, and foundations, as it minimises the risk of sulphuric acid attacks, which can cause significant damage to structures.

In addition, SRC also reduces the risk of corrosion of reinforced steel in saltwater environments, making it an ideal choice for structures built in coastal regions. Its unique composition provides increased durability in saline areas, allowing it to withstand the harsh environmental conditions that are common in these regions.

Low Alkali Cement

Low alkali cement is a type of cement that reduces the potential for damage due to alkali-aggregate reaction (AAR). It is highly suitable for use in various structures such as bridges, dams, sea walls, water-retaining structures, and submerged structures.

Additionally, low-alkali cement is highly effective in structures such as swimming pools, basements, retaining walls, large foundations, and piles, where the risk of alkali carbonate reaction is high. It is also equally effective for general-purpose usage. Overall, it is an essential component for structures that require long-lasting durability and resistance to damage.

Low Heat of Hydration Cement

The low heat of hydration cement is characterised by its ability to produce a lower amount of heat during the cement and water reaction, which makes it highly useful in structures that employ mass concreting.

This type of cement is particularly effective in large-scale construction projects such as dams, hydropower projects, and submerged structures. It is also highly effective in heavy retaining walls, piers, roads, workroom surfaces of factories, and chemical plants. Overall, it is essential for structures that require long-lasting durability and resistance to damage, while minimising the risk of thermal cracking due to excessive heat.

Pamir Cement (Green Cement)

Pamir cement, also known as green cement, is a high-quality and cost-effective cement that is ideal for a variety of construction purposes. It is particularly suitable for brick/block masonry, plastering, and flooring, and it is equally effective for plain and reinforced concrete work in normal structures.

In addition, Pamir cement is also suitable for blocks, kerb stones, and pavers, as it provides a smooth finish with strong edges. Its high saline content also provides early strength compared to other types of cement. Furthermore, it has a lighter tone, which enhances its aesthetic appeal in construction projects.

Local and Export Sales

FCCL’s cement is sold locally through an extensive network of authorised dealers in Pakistan and can be supplied for various construction projects, such as residential and commercial buildings. Customers can also purchase cement online.

In addition to local sales, FCCL exports its cement to various regions, such as Afghanistan and Central Asia, via the Torkham, Ghulam Khan, and Chaman Borders. The company also exports its cement by sea to regions such as Africa and the Far East.

Operations

FCCL deals in 5 different operations:

- Manufacturing process

- Quality assurance

- Going green

- Other projects

- Health, safety and environment

Manufacturing Process

At the cement plant, FCCL follows a meticulous process to ensure the production of high-quality cement. It carefully selects the finest raw materials, mainly limestone and clay, and uses the dry process to manufacture them. The raw materials are first extracted from quarries, crushed, and then mixed to create the raw mix.

This is then ground in a raw mill and burned in a rotary kiln at an incredibly high temperature of 1450°C. During the burning phase, complex chemical reactions take place, resulting in the formation of a clinker. The cement mill finally grinds the clinker and gypsum together to produce a fine powder known as cement.

Quality Assurance

As pioneers in the industry, FCCL introduced a “Mobile Cement Testing Lab” vehicle that carries all the necessary equipment for cement and concrete testing. This vehicle is the first of its kind in Pakistan, and customers can use the toll-free number displayed on the vehicle to register complaints, give feedback, seek expert advice, and even place orders for cement online.

FCCL has also employed a concrete specialist who not only resolves related issues but also provides guidance on ideal concrete mix solutions. FCCL has established an Integrated Management System that encompasses the entire process of manufacturing and selling.

This system is fully compliant with a set of rigorous standards and has been certified by the TUV Austria Bureau of Inspection and Certification.

- ISO 9001:2015 (Quality Management System)

- ISO 14001:2015 (Environment Management System)

- ISO 45001:2018 (Occupational Health & Safety Management System)

Going Green

The process of cement manufacturing releases harmful gases into the environment, primarily during the calcination process and the use of fossil fuel-generated power. Developed nations have already implemented measures to minimise carbon dioxide emissions, and FCCL takes pride in spearheading similar efforts in Pakistan.

It has implemented a strategy to ensure compliance with both national and international emission standards. This includes several measures to reduce emissions, such as developing cement that produces fewer emissions, utilising waste heat for power generation, replacing fossil fuels with alternative fuels, introducing cementitious products, planting trees, and conserving water.

FCCL’s introduction of “Pamir cement” (also known as green cement) in both local and international markets aligns with its commitment to promoting a safe and clean environment. It is not only of high quality but also contributes to the reduction of overall CO2 emissions in the atmosphere.

Health and Safety

The company complies with all relevant regulations and adheres to international industry standards. This minimises the number of accidents in daily operations and activities. FCCL conducts extensive training programs on a regular basis to improve the awareness and efficiency of the employees.

Its plants are equipped with an efficient fire safety system, including fire hydrants, two fire tenders, and a team of highly skilled firefighters capable of handling any emergency within the plant and surrounding areas. FCCL has a zero-tolerance policy towards health and safety breaches.

Fauji Cement Price

As of March 2023, the cement price in Pakistan for a 50-kg Fauji bag is around Rs. 1095-1100.

Frequently Asked Questions (FAQs)

Q: What is Fauji Cement Company Limited (FCCL)?

A: FCCL is a renowned cement manufacturer based in Pakistan, known for producing high-quality cement products.

Q: What is FCCL’s contribution to Pakistan’s cement industry?

A: FCCL has been a major contributor to Pakistan’s cement industry, providing employment opportunities and boosting the country’s economic growth.

Q: What are FCCL’s operations?

A: FCCL’s operations involve the manufacturing and distribution of cement products.

Q: What is FCCL’s commitment to sustainability?

A: FCCL has implemented several measures to reduce its carbon footprint. This includes the development of “Pamir cement” (green cement), utilising waste heat for power generation, and planting trees.

Q: What is FCCL’s commitment to health and safety?

A: Health and safety are core values and top priorities for FCCL. The company complies with all applicable regulations and has implemented international industry standards to minimise incidents and continually enhance its health and safety standards in daily operations and activities.

Q: What are some of FCCL’s notable achievements?

A: FCCL has won several awards. This includes the Best Corporate Report Award, the Best Sustainability Report Award, and the Best HR Practices Award, among others.

For more related information, visit Graana.com.